Interesting Tech Projects

Leveling a RepRap Bed with Three Screws

The majority of beds on RepRap 3D printers are leveled using four adjustment screws, one at each corner, and therefore most if not all leveling instructions are for that situation. The RepRapPro printers are different in that they have only three screws and there is little detailed information on how to use them to level the bed. Here are the steps I use.

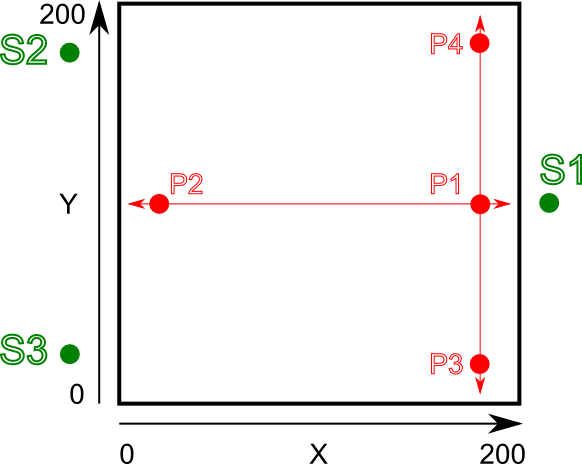

This is a view of the bed looking from above and standing at the front of the printer.

The home position of X = 0, Y = 0 is at the bottom left. Green dots indicate the positions of the adjustment screws for leveling the bed. Red dots indicate the measurement positions of the hotend (the nozzle). It is important to note that when at normal operating temperature the bed and hotend move closer together through expansion from the heat. Therefore leveling must be performed while hot.

- Set the bed to 60C and the hotend to 150C. I use a slightly lower temperature on the hotend to stop oozing of filament during the process. You can optionally retract or remove the filament if you prefer

- Loosen all three adjustment screws, S1, S2 and S3. I.e. the bed is raised to it’s maximum height while still being securely attached to the Y axis.

- Move the Z endstop thumbwheel to a conservative position so that when Z is homed the hotend won’t crash into the bed.

- Move hotend to position P1 (X = 200, Y = 100)

- Repeatedly adjust the Z endstop thumbwheel and home the Z axis until the hotend is the thickness of a piece of paper above the bed.

- Move hotend to position P2 (X = 0, Y = 100) and home Z

- We now need to adjust the height of the bed so that the hotend is the thickness of a piece of paper above the bed. The left side of the bed can be raised and lowered by adjusting screws S2 and S3 in parallel – i.e. turning them both in the same direction and by the same amount.

- At this point the hotend should now be perfectly aligned with the bed along the horizontal red line shown in the diagram. What we still don’t know is if the bed is tilted towards the front or back, which we will now check.

- Move the hotend to position P3 (X = 200, Y = 0) and home Z

- Adjust the height of the front right corner of the bed so that the hotend is the thickness of a piece of paper above the bed. This corner can be adjusted by using screw S2 only. For example, if we turn S2 clockwise we will lower the rear left corner which will raise the front right corner, moving it closer to the hotend.

- Move the hotend to position P4 (X = 200, Y = 200) and home Z

- Adjust the height of the rear right corner of the bed so that the hotend is the thickness of a piece of paper above the bed. This corner can be adjusted by using screw S3 only. For example, if we turn S3 clockwise we will lower the front left corner which will raise the rear right corner, moving it closer to the hotend.

- At this point the hotend should now be perfectly aligned with the bed along the vertical red line shown in the diagram. Alignment in two directions means that the entire bed should be level. The problem with the two previous adjustments is that they slightly affect other areas of the bed at the same time, which we don’t want. The way to minimize this is to now repeat the process again by going back to step 4.

- Finally double-check the height of the hotend above the bed at the center (X = 100, Y = 100). It should be the thickness of a piece of paper.

| Print article | This entry was posted by Andy on March 3, 2013 at 2:55 am, and is filed under 3D Printing. Follow any responses to this post through RSS 2.0. Both comments and pings are currently closed. |

Comments are closed.

about 10 years ago

Excellent info I have had my printer for over a year and never had a great print and I am sure it is due to the bed level I will try this method and see what happens. Many Thanks for this fantastic info.

about 8 years ago

Thanks for sharing your knowledge, the article is quite good. However you seems to have missed to explain the use of screw S1. The S1 is only mentioned in bullet#2 “Loosen all 3 screw”, 🙂 I guess it would play some role in levelling left and right side (P1 to P2).

about 8 years ago

S1 is not needed again. When S1 is loosened in step 2 it is setting a reference height for the center-right side of the bed, which we use in step 5. All other leveling is based on that reference height. Changing it would mess everything up.