Interesting Tech Projects

Involute Gears in Alibre Design

The most common type of gear is the involute gear, which provides smooth and efficient operation. A gear is defined by the following parameters:

- Pitch diameter (diameter of gear)

- Diametral pitch (tooth size)

- Number of teeth

- Pressure angle (commonly 14.5, 20 or 25 degrees)

The pressure angle defines the shape of a tooth. For two gears to mesh the pressure angle and diametral pitch must be the same (i.e. the shape and size of the teeth must match). There is a simple relationship between pitch diameter, diametral pitch and number of teeth so when defining a gear we only need to specify two of those parameters.

The ability to create involute gears is included in python-based ADScript. Let’s see how.

NumberofTeeth = 20

PitchDiameter = 30

PressureAngle = 20

InputGear = Part("Input Gear")

XYPlane = InputGear.GetPlane("XY-Plane")

GearSketch = InputGear.AddGearNP("Gear Profile", NumberofTeeth, PitchDiameter, PressureAngle, 0, 0, XYPlane)

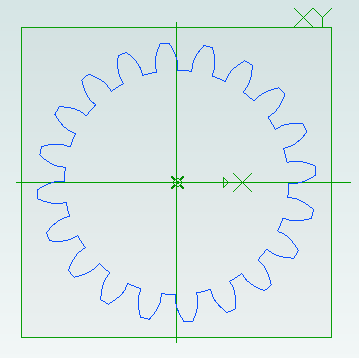

This script creates a new part called Input Gear and then adds a sketch to it on the XY-plane for the profile of a gear by calling AddGearNP. NP shows which two parameters are used, N = number of teeth and P = pitch diameter.

The 0, 0 defines the coordinates of the center of the gear.

Once the gear has been created we can read out the diametral pitch:

DiametralPitch = GearSketch.DiametralPitch

There are two other functions that we can call to create gears, depending on which two parameters we wish to use.

GearSketch1 = MyPart.AddGearDN("Gear Profile", DiametralPitch, NumberofTeeth, PressureAngle, 0, 0, XYPlane)

PitchDiameter = GearSketch1.PitchDiameter

GearSketch2 = MyPart.AddGearDP("Gear Profile", DiametralPitch, PitchDiameter, PressureAngle, 0, 0, XYPlane)

NumberofTeeth = GearSketch2.NumberofTeeth

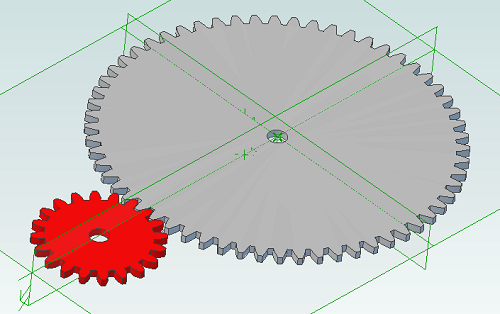

Here is an example script that shows how we can create two gears that can be used together to provide a 3:1 reduction ratio:

# all values are in millimeters

Units.Current = UnitTypes.Millimeters

# pressure angle has to be the same for both gears

# common values are 14.5, 20 and 25

# larger pressure angle = stronger teeth

PressureAngle = 20

# thickness of gears

Thickness = 2

# shaft diameter

ShaftDiameter = 5

# define input gear - 20 teeth and 30mm pitch diameter

Gear1Teeth = 20

Gear1Diameter = 30

# create input gear using number of teeth and pitch diameter

Gear1Part = Part("Input Gear")

Gear1 = Gear1Part.AddGearNP("Gear Profile", Gear1Teeth, Gear1Diameter, PressureAngle, 0, 0, Gear1Part.GetPlane("XY-Plane"))

Gear1.AddCircle(0, 0, ShaftDiameter, False)

Gear1Part.AddExtrudeBoss("Gear", Gear1, Thickness, False)

# diametral pitch must be the same for both gears as this defines tooth size

# use diametral pitch for output gear from input gear calculated value

Gear2DiametralPitch = Gear1.DiametralPitch

# we want a ratio of 1:3 so output gear has three times the number of teeth

Gear2Teeth = Gear1Teeth * 3

# create output gear using number of teeth and diametral pitch

Gear2Part = Part("Output Gear")

Gear2 = Gear2Part.AddGearDN("Gear Profile", Gear2DiametralPitch, Gear2Teeth, PressureAngle, 0, 0, Gear2Part.GetPlane("XY-Plane"))

Gear2.AddCircle(0, 0, ShaftDiameter, False)

Gear2Part.AddExtrudeBoss("Gear", Gear2, Thickness, False)

# get the calculated pitch diameter of the output gear

Gear2Diameter = Gear2.PitchDiameter

# calculate distance between gear centers so we know how far apart the shafts need to be

print "Distance between gear centers = %fmm\n" % ((Gear1Diameter + Gear2Diameter) / 2)

And the result:

| Print article | This entry was posted by Andy on April 25, 2013 at 11:26 am, and is filed under Computer Aided Design, Software Engineering. Follow any responses to this post through RSS 2.0. Both comments and pings are currently closed. |

Comments are closed.