Interesting Tech Projects

Scripting Metric Screws in Alibre Design

Creating screws is tedious. There are lots of diameter and length combinations and there is more to a screw than first meets the eye. Creating a parts library containing lots of variations is a perfect use for ADScript.

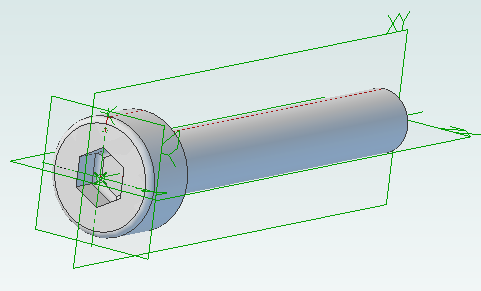

Here is a M3 x 20mm socket cap screw generated from the script below.

This screw is modeled to the ISO 4762 standard. Notice the threads are missing? Modeling the threads is generally a waste of time and resources as the aim is to ensure a screw fits, is long enough and there is enough clearance to install it.

# Creates a metric socket cap screw using ISO 4762

# See: http://practicalmaintenance.wordpress.com/2009/01/30/socket-head-cap-screws-article-13/

# Size of screw

Diameter = 3.0

Length = 20.0

# Measurements table containing H, F, E, T, C from web page

MetricData = {}

MetricData[1.6] = [3.14, 2.0, 1.73, 0.7, 0.16]

MetricData[2.0] = [3.98, 2.6, 1.73, 1.0, 0.2]

MetricData[2.5] = [4.68, 3.1, 2.3, 1.1, 0.25]

MetricData[3.0] = [5.68, 3.6, 2.87, 1.3, 0.3]

MetricData[4.0] = [7.22, 4.7, 3.44, 2.0, 0.4]

MetricData[5.0] = [8.72, 5.7, 4.58, 2.5, 0.5]

MetricData[6.0] = [10.22, 6.8, 5.72, 3.0, 0.6]

MetricData[8.0] = [13.27, 9.2, 6.86, 4.0, 0.8]

MetricData[10.0] = [16.27, 11.2, 9.15, 5.0, 1.0]

MetricData[12.0] = [18.27, 13.7, 11.43, 6.0, 1.2]

MetricData[16.0] = [24.33, 17.7, 16.0, 8.0, 1.6]

MetricData[20.0] = [30.33, 22.4, 19.44, 10.0, 2.0]

MetricData[24.0] = [36.39, 26.4, 21.73, 12.0, 2.4]

MetricData[30.0] = [45.39, 33.4, 25.15, 15.5, 3.0]

MetricData[36.0] = [54.46, 39.4, 30.85, 19.0, 3.6]

MetricData[42.0] = [63.46, 45.6, 36.57, 24.0, 4.2]

MetricData[48.0] = [72.46, 52.6, 41.13, 28.0, 4.8]

MetricData[56.0] = [84.54, 63.0, 46.83, 34.0, 5.6]

MetricData[64.0] = [96.54, 71.0, 52.53, 38.0, 6.4]

CapDiameter = MetricData[Diameter][0]

FilletTransitionDiameter = MetricData[Diameter][1]

HexHoleDiameter = MetricData[Diameter][2]

HexHoleDepth = MetricData[Diameter][3]

RimFilletRadius = MetricData[Diameter][4]

# all values are in millimeters

Units.Current = UnitTypes.Millimeters

# Create part

Screw = Part("Cap Screw M%dx%d" % (Diameter, Length))

# body

Profile = Screw.AddSketch("Profile", Screw.GetPlane("XY-Plane"))

Profile.AddLines([0, 0, 0, CapDiameter / 2, Diameter, CapDiameter / 2, Diameter, Diameter / 2, Diameter + Length, Diameter / 2, Diameter + Length, 0, 0, 0], False)

Screw.AddRevolveBoss("Body", Profile, Screw.GetAxis("X-Axis"), 360)

# hex hole

HexHole = Screw.AddSketch("Hole", Screw.GetFace("Face<5>"))

HexHole.AddPolygon(0, 0, HexHoleDiameter, 6, False)

Screw.AddExtrudeCut("Hex Hole", HexHole, HexHoleDepth + ((FilletTransitionDiameter - Diameter) / 2.0), True)

# fillet from cap to shaft

Screw.AddFillet("Cap Joint", Screw.GetEdge("Edge<21>"), (FilletTransitionDiameter - Diameter) / 2.0, False)

# fillet at bottom of hex hole

Screw.AddFillet("Hex Hole Bottom", [Screw.GetEdge("Edge<5>"), Screw.GetEdge("Edge<9>"), Screw.GetEdge("Edge<12>"), Screw.GetEdge("Edge<21>"), Screw.GetEdge("Edge<18>"), Screw.GetEdge("Edge<15>")], (FilletTransitionDiameter - Diameter) / 2.0, False)

# fillet on rim

Screw.AddFillet("Cap Rim", Screw.GetEdge("Edge<35>"), RimFilletRadius, False)

| Print article | This entry was posted by Andy on April 10, 2013 at 1:35 pm, and is filed under Computer Aided Design, Software Engineering. Follow any responses to this post through RSS 2.0. Both comments and pings are currently closed. |

Comments are closed.

about 9 years ago

Andy, brilliant! Many thanks for sharing all this. It works well with my version of Alibre: v12.0

Minor typo in line 44 should read:

Profile.AddLines(….

Ha ha, I’m sure you were just testing to encourage proper understanding 🙂

Thanks again

Phil

about 9 years ago

Fixed the typo – thanks! I’m glad it is working with V12. Shows how stable the Alibre/Geomagic API has been!